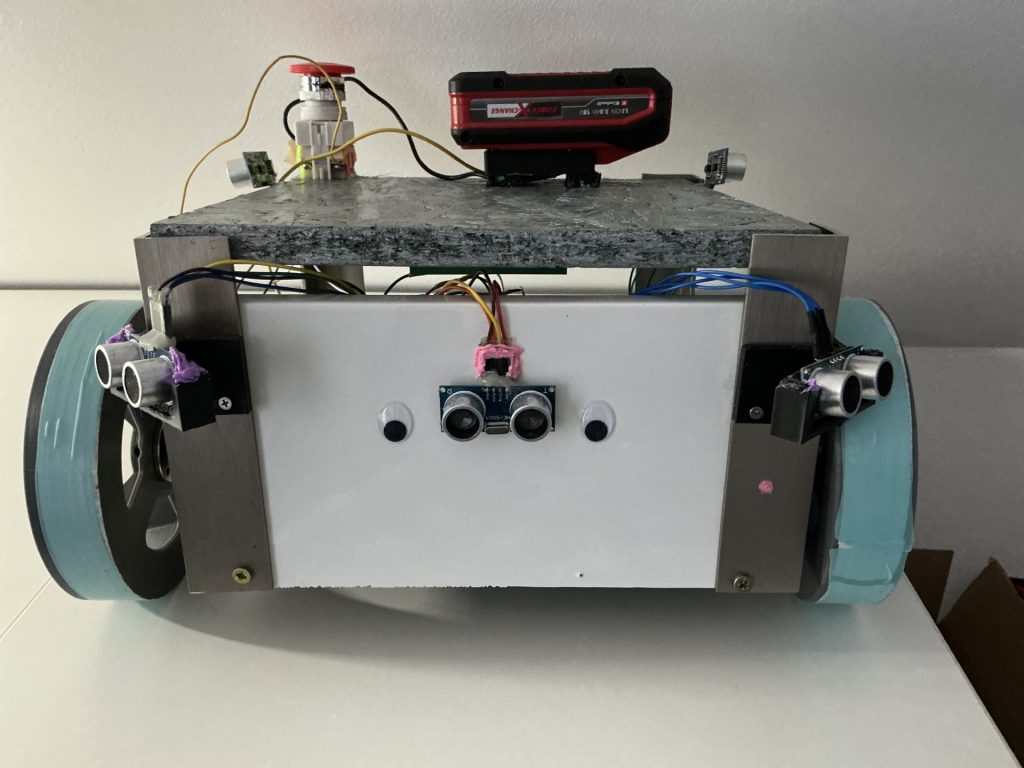

We have now mounted the ultrasonic sensors at the front of the system at a 45-degree angle using custom-designed 3D-printed holders. These sensors were carefully positioned to ensure optimal coverage and then fully wired to the Arduino for data processing.

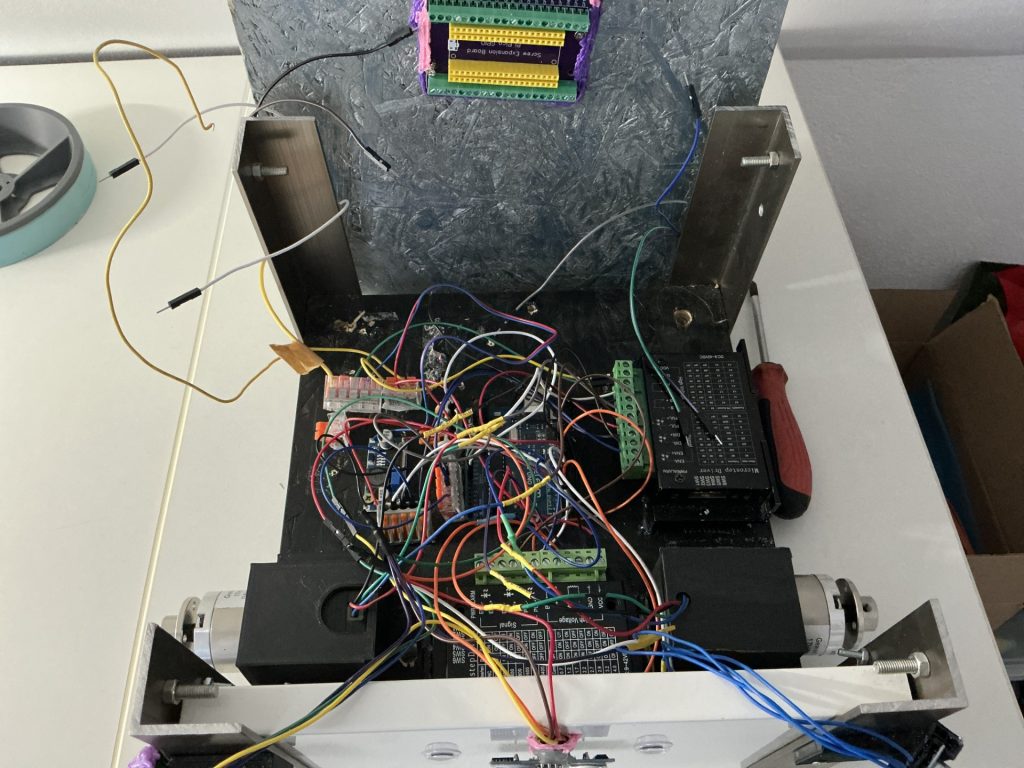

On the underside of the upper plate, we securely attached a Raspberry Pi Pico, which is responsible for controlling the motors. The Pico was connected to both the motors and the corresponding motor driver boards, ensuring reliable power delivery and precise motor control.

The drive system consists of 3D-printed wheels that were attached to the motors using flange couplings. To improve traction and grip, the wheels were wrapped with resistance bands (TheraBands), which significantly enhance contact with the ground.

Finally, we mounted a power drill battery on the upper plate to serve as the main power supply for the entire system, providing sufficient energy for both the control electronics and the motors.

(author: Samuel)